Your Trusted Partner in Pulp & Paper Industry Solutions

VTSSA Enterprises is a trusted affiliate partner of C2C Consultancy, offering complete engineered solutions for the pulp & paper industry — from design and supply to installation and commissioning.

Our in-house expertise, combined with cutting-edge technology, enables us to provide custom-engineered systems like Hood & PV Systems, Heated False ceiling, Building hall ventilation system, Chemicals and automatic dosing unit, Water tampering unit for Film Size press & Puddle type size press, Electrical panels, Automation panels and complete automation solution — designed for reliability and long-term value.

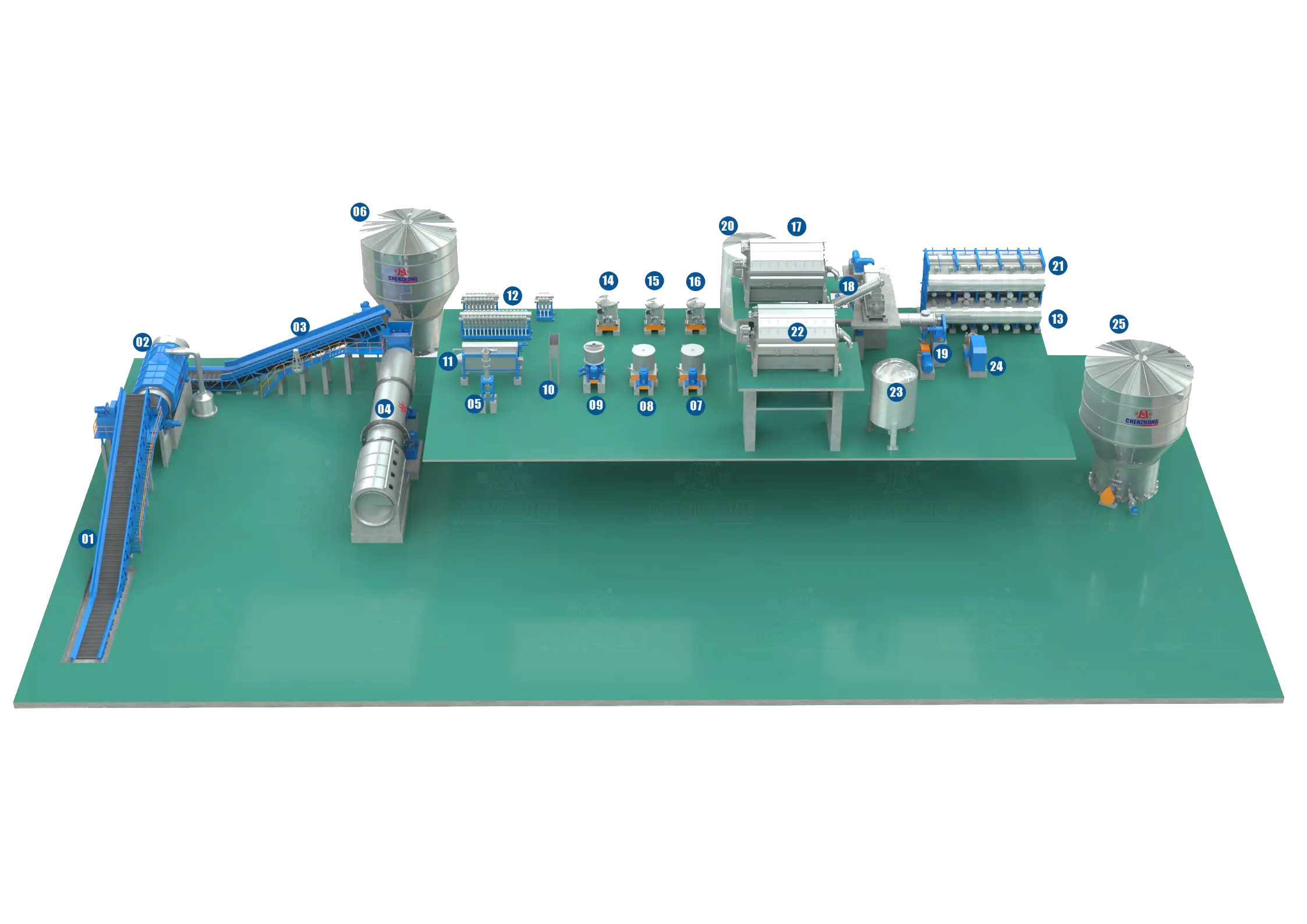

Backed by strong global partnerships with leading OEMs such as Maflex, OPD, Chenzhong, Txuan, Taiding, Dawei, Tianli and Pnshar, we deliver high-performance systems that improve efficiency, energy optimization, and paper quality.